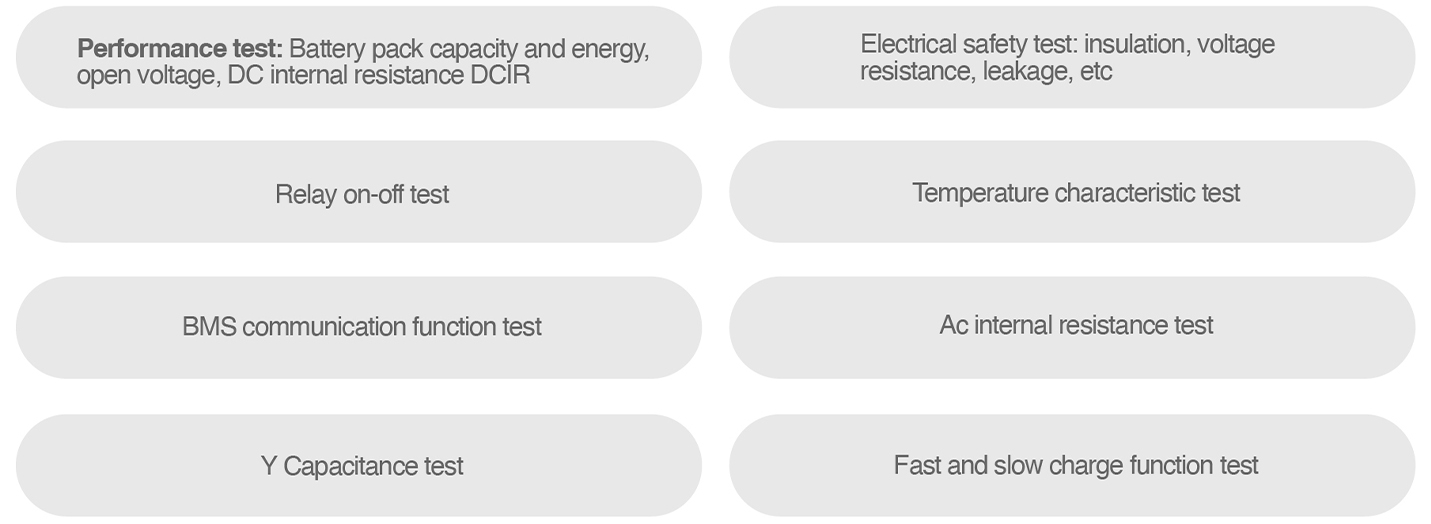

Offline testing is an important part of the battery pack production process, through the safety test, insulation performance test, BMS functional test, charge and discharge simulation test to check the full performance of the battery pack, the quality of the battery pack and the group characteristics of the comprehensive assessment to ensure that the battery module/battery pack zero defect shipment and use safety.

Our battery offline comprehensive test system integrates charge and discharge equipment and EOL offline test equipment, providing automated and intelligent test solutions for battery pack offline test. The test system automatically identifies product information by scanning the bar code of the battery pack, and performs corresponding test procedures on the battery pack. Through the large-capacity charge and discharge simulation test, the charge and discharge characteristics of the battery pack are verified to be in good cooperation with the BMS. Through the AC and DC voltage resistance and insulation resistance test, the safety of the battery pack is ensured.

The test system software has powerful data management and analysis functions, which can be seamlessly connected with MES, automatically upload test data and test reports, and monitor the test running status in real time, greatly improving the automation level of the production line and improving production efficiency.

Comprehensive test solution for production line